Looking for a quick, high-quality solution for your small volume (200 PCS )plastic needs?

With so many options out there, it can be tough to know where to turn.

Injection molding from Topworks is the perfect solution – we’ll take care of everything so you can focus on your business.

With our low volume injection molding manufacturing dominance, you can intend to build your plastic parts in cost-conscious manner.

The low volume injection molding or Rapid Manufacturing method applies to many indispensable industries that make plastic parts by injection molding.

The technology can be used to minimize the molding time for your products, to produce pre-mass quantities with real material, or to construct small quantities of finished products. Not surprisingly, molding costs of low volume production are significantly lower than those of conventional methods.

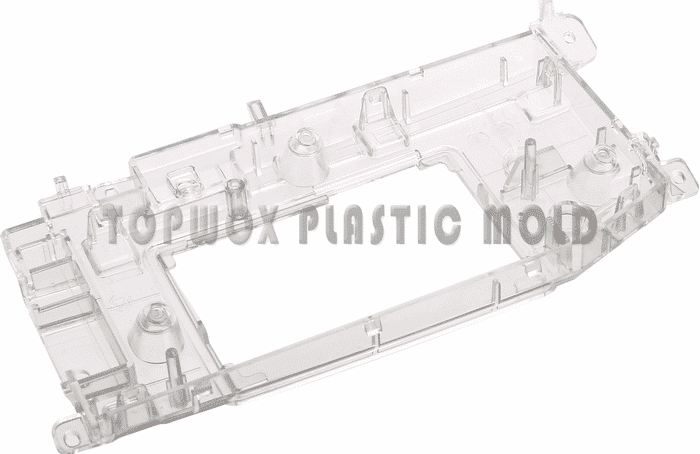

A case for study:

finished vacuum casting model

final assembly

Topworks’ low volume injection molding capabilities

We offer injection molding low-volume manufacturing services, providing our clients with the ability to manufacture hundreds of plastic parts so that their products can be brought to market.

Perhaps our prototyping services would be of benefit to you if you only need a few parts or prototypes. Throughout the prototyping and production process, we at Topworks are by your side.

We encourage you to contact our team once you are ready to begin your next project and upload your 3D CAD files for a free quote.

The Topworks team analyzes the product design for manufacturing feasibility and offers recommendations on how to develop a product that can be produced in low-volume injection molding. Material selection also plays a crucial role in the development process.

“I’m glad to inform you that all plastic parts are perfect!!! We are delighted, and therefore there are good chances to continue our relationship for any coming new project.”

CRISTIANO

ITALY

“Steven is a very detail-oriented project manager and engineer who can solve problems creatively and also provides excellent service. It was a pleasure working with him.”

DAVID

USA

Topworks can provide resin material model and type options that describe the physical properties of the different options if the customer does not know what resin type to use for the product. Topworks will need to know the product function and the range of uses of the product, along with other specifications such as UV proofing or flame class requirements. This will enable them to make an appropriate recommendation.

We chooses the most feasible and economically advantageous tool steel and structure based on the customer’s design or sample. A manufacturing method that Topworks finds suitable to meet the needs of its customers is also chosen.

Customers can choose between 3D printing or CNC machining for the creation of prototypes. To avoid later tool modification and higher costs, this is done before any injection tools are built.

Topworks customers benefit from flexible communication between departments as well as flexible production schedules. Two to three production shifts are available to meet the mold requirements of our customers. We have 14 sets of injection machines ranging from 80 to 1,000 tons in capacity.

In addition, there is a 2000 square meter warehouse where the production molds are kept on solid shelves. Tooling maintenance is conducted regularly to keep production running smoothly.

Low Volume Injection Molding : What Is It?

Low volume injection molding is a flexible and recognizable alternative to traditional, high volume injection molding. It is ideal for short runs of highly customized parts, or for prototyping new designs.

Low volume injection molding has a number of vital advantages over traditional high volume injection molding. First, it is much more flexible, allowing for shorter runs of highly customized parts. Second, it is perfect for prototyping new designs. Third, low volume injection molding generally requires less upfront investment than high volume injection molding.

Depending on the manufacturing method, low-volume injection molded products can be production-quality parts in smaller quantities, usually less than 1,000 unique pieces.

It’s a popular approach for many products, since it enables a rapid product development cycle, offers a fast route from early prototypes to mass production, as well as reducing tooling and material investment.

Why low volume injection molding Better

What are the ways that low-volume manufacturing can reap huge fruits for your business? To name a few:

Build a link between prototyping and mass production

Prototyping is a critical step in ensuring that products meet customer expectations before mass production making it an essential part of product development for businesses. By creating a strong connection between prototyping and mass production companies can save time and money.

There are different approaches to building this vital link. One way is by partnering with low volume injection molding firms known for their expertise in short run productions, which enables them to work closely with businesses developing new products.

Rapid prototyping techniques are also useful as they facilitate speedy prototype creation for testing before committing resources towards mass production

Low minimums to reduce costs

Businesses must pay close attention to cost reduction measures in any project undertaking, including injection molding where low minimums can lower expenses considerably by reducing cavities or lowering order quantities. The notion that larger purchases equal lower prices per item is something we’ve all heard before – but this concept isn’t universally applicable across all products or industries.

Connect emerging markets quickly

There are a number of ways to connect emerging markets quickly. One is to use a low volume injection molding . This type of injection molding is designed for small businesses that want to produce a limited number of products.

It is also effortless for entrepreneurs who are looking to start a business in an emerging market. Another way to connect to an emerging market is to use a 3D printer. This type of printer can be used to create prototypes or small batches of products. It is also possible to use crowdfunding platforms to raise money for a business venture in an emerging market.

Shorten product lifecycles quickly

Low volume injection molding (LIM) is a process that allows manufacturers to acquire small quantities of parts quickly and efficiently.

The main advantages of low volume injection molding are its speed and flexibility. LIM can shorten product lifecycles by allowing businesses to quickly construct and test prototypes. This process is also much more flexible than other manufacturing methods, as it can be easily adapted to changes in design or specifications.

Overall, low volume injection molding is an efficient and versatile manufacturing process that can be used to create high-quality parts in a shorter timeframe.

Streamline the design process

The injection molding process can be further streamlined by working with a low volume injection molding specialist. Low volume injection molding specialists are experts in designing and manufacturing molds for small production runs.

They can help streamline the design process by providing advice on part geometry, material selection, and mold construction.

They also have the experience and knowledge to help engineers optimize their designs for injection molding. Low volume injection molding specialists can produce prototypes in as little as 3 weeks. However, large production runs can take up to 2 months to complete.

Prevent many hidden problems

There are many merits to low volume injection molding, but one of the most important is that it can help prevent hidden weakness. By producing smaller quantities of parts, you can more easily identify any potential issues and make corrections before they become costly problems.

If you’re looking to get your product to market quickly and efficiently, low volume injection molding is the way to go. By producing smaller quantities of parts, you can more easily identify any potential issues and make the necessary changes before going into full production.

Additionally, low volume injection molding allows for more flexibility in design, as you can easily make changes to the mold during the production process. This means that you can iterate on your design until it’s perfect, without incurring huge costs or delays.

Prototype Molds for low volume injection molding

In order to evaluate the aesthetics and function of a newly designed product, prototype molds are needed to make samples of the new product. Tests on molded samples are more accurate than those on hand-made (machined or assembled) samples.

Furthermore, it may produce a more accurate result (and be less expensive) than a computer simulation. Taking shortcuts everywhere is possible, as long as the material used to construct the mold is sufficiently strong and can withstand the heat and pressure of the plastic injection. This applies to mold materials such as mild steel, aluminum, even plastic (epoxy, etc.).

It is usually unnecessary to maintain close tolerances. Surface appearance (polishing, engraving, even flashing) won’t be an issue in general. As long as the plastic has cooled enough, the molded sample can be removed from the mold without cooling channels.

Additionally, ejector mechanisms are not always necessary. There may be no need for more sophisticated ejector pins than one or two air jets directed at the edge of the product at the parting line. For example, loose inserts in the mold can be used to produce threads in the product, which are then ejected with the finished product and unscrewed by hand.

Also, loose inserts can be used in areas that would otherwise require side cores, such as on the sides of a product.

Once the molded piece is cool, it can be machined with rounds or simple openings. This is merely a sample of the mold features that can be eliminated to simplify stacks and to lower the cost of prototype molds.

It is also possible to mount prototypes in a mold shoe, saving even more money if prototypes are frequently needed. An edge gate might consist of sprue and a short runner or a simple sprue gate directly into the product. A manual cut will then be performed on the gate.

| Steps | Brief Description |

|---|---|

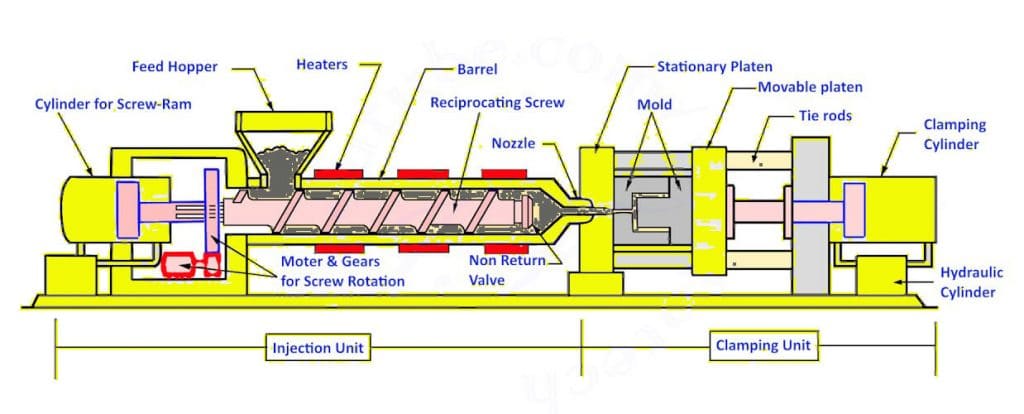

| Clamping | Injection molds are closed with tremendous force before the plastic is injected into them, preventing any opening during injection and ensuring that the mold does not open when the plastic is injected. |

| Injection | Generally, raw plastic materials in the form of small pellets are placed in the feed zone of a reciprocating screw when they are fed into an injection molding machine. The plastic pellets are heated and compressed as they pass through heated areas of the barrel. The machine tightly controls the dosage of plastic and injects the melted plastic into the mold after the proper dosage reaches the screw and the mold is fully clamped. The molten plastic is pushed into the cavity under high pressure. |

| Cooling | The molten plastic begins to cool upon contact with the mold surfaces. As the plastic part cools and solidifies, it takes on its final shape and rigidity. Cooling times for plastic molded parts vary based on the material’s thermodynamic properties, wall thickness, and part dimensions. |

| Ejection | After the plastic part has cooled inside the mold and the clamp is removed to open the plastic injection mold, the screw prepares for a new injection of plastic. The machine is equipped with a mechanical mechanism to eject the plastic injection molded part. The molded part is removed from the mold, and the mold can be used again for the next part after the new part is fully ejected. |

Injection molding simplifies the process of creating high volumes of identical parts with consistent and fundamental characteristics and quality. The part is ejected quickly from the mold after cooling. The press closes after the component is ejected, repeating the process. Plastic injection molding is used to manufacture everyday products. Since injection-molded parts are expensive to manufacture, they were traditionally made in large quantities. Over time, hardened steel molds recoup investment and lower cost-per-part as they are durable and can be tool for weeks or months. As markets change, manufacturers are adapting their operations so they can exploit new, more efficient methods as markets evolve – as evidenced by the shift toward custom and small batch products. This is where low-volume injection molding comes into play.

Those benefits of low volume injection molding

For low-volume injection molding, softer aluminum inserts are more welcome to hardened steel molds, since they are usually easier to make and cheaper. Hardened steel molds are obviously more durable, but when producing low volume parts, these molds do not need to be.

Tooling costs can be reduced and production schedules shortened by strategic use of soft molds. Injection molding for low-volume parts involves less than 1,000 pieces. To the layperson, that number seems a bit high, but compared with high-volume production, it is still relatively low.

There is no official cutoff for aluminum molds, but 1,000 acts as general benchmark for when they become less cost-effective than hardened steel molds. While traditional molds require hardened steel, the initial investment is significant. Aluminum and lower-grade steel molds can be produced more quickly and for less cost.

They make it possible to develop prototypes and produce viable parts without committing to large minimum orders while improving part design and manufacturing as needed.

By starting production soon, manufacturers can accelerate their time-to-market significantly, thereby reducing their time to see a return on investment.

so that’s a low volume injection molding advantage—summed up like this:

- Lower investment costs – Lower tooling costs compared to conventional methods due to the small batch sizes and short lead times intensely .

- Quick delivery – Injection molds can be designed and delivered within weeks, allowing for fast turnaround times.

- Cost savings – Low initial investment costs allow you to produce parts more cost effectively in large quantities to reap huge fruits.

- Design flexibility – You can use traditional or rapid prototyping techniques (such as 3D printing) to create complex designs that cannot be manufactured using conventional methods.

- Manufacturing flexibility – The process is highly adaptable to changes in design and production, allowing for rapid response to customer requirements.

Design tips for low-volume application

In designing parts for manufacturability at low volumes, there are a few things to keep in mind, such as general part complexity, draft, wall thickness, and surface finish. When working with aluminum, you do not want to build in lifters or side actions common to complex builds.

When such operations wear down the tool – soft aluminum cannot withstand such pressure – low-hardness steels like P20 are the best replacement material.

A draft is a design feature that makes ejection from the mold easier. A rectangular pan would make removing a cake difficult if it were truly rectangular. Cakes can easily be removed from the pan due to its rounded edges and tapered sides. Similarly, injection-molded parts can be removed from their molds.

A vertical face should have at least 0.5 degrees of draft, although two or three degrees is better if possible. In some cases, 5 degrees of draft may be necessary. When working with thermoplastic materials, thicker walls don’t necessarily make a component stronger or more effective.

Walls should remain between 0.040 and 0.140 inches (1 to 3.5 millimeters) thick across the part’s entirety to reduce the likelihood of warping or sinking of the part during cooling. Forgoing unnecessary surface finishes on molds can also reduce tooling costs and lead time.

If you don’t need a very smooth surface on the part, then there’s no need to hand-polish the mold cavity with diamond buffs. Lowering production costs and improving production times can be achieved using the most cost-efficient finish for a given part.

| Materials | Plastic manufacturers often select a standard grade of plastic for a similar application or based on supplier recommendations. However, these resins may not be optimal. In plastic selection, there are many factors to consider, including: |

|---|---|

| Heat: The stress created by normal and extreme conditions of use and during the assembly, finishing, and shipping processes. | |

| Chemical resistance is a property affecting part performance when solids, liquids, or gases are in contact. | |

| Agency approvals: Standards developed by the government or the private sector for properties like heat resistance, flammability, and mechanical and electrical performance. | |

| Assemblage: During the assembly process at plastic factory, the plastic is bonded, mechanically fastened, and welded. | |

| Finish: Ability of the material to come out of the mold with the desired appearance values, such as gloss and smoothness. | |

| Price: The price of resin, costs of manufacturing, maintenance, assembly, disassembly, and other costs to reduce labor, finishing, and tools. | |

| Access: The availability of resin from the point of view of the amount required for production of plastic manufacturer. | |

| Draft | A draft angle makes it easier to remove a cooled, finished part from a mold . Draft angles are an essential component of injection molding. Minimizing friction during the part release process can achieve a uniform surface finish and reduced wear and tear on the mold at plastic factory. |

| An angle of the draft is measured according to the direction of pull. Draft angles of at least 0.5° for the cavity and 1.0° for the core are suggested by most design engineers for parts with sufficient draft. The tool must also be designed with more draft if a textured surface is desired and steel shut-off surfaces. | |

| Wall Thickness | The wall thickness of injection molded parts is also an important consideration. An injection molded part from plastic products supplier with a proper and uniform wall thickness is less prone to structural and cosmetic problems. |

| Most resins have a typical wall thickness ranging from .04 – .150. Yet, it is recommended that you obtain thickness specifications for your material(s) of choice by consulting with an injection molder/design engineer and plastic manufacturer. | |

| Wall thickness should be analyzed during the design process to ensure that parts don’t sink, warp, or become non-functional. | |

| Ribs | As ribs are used to reinforce the walls of your injection molded parts without increasing their thickness, they are a valuable component in injection molded parts. Rib design should reduce mold flow length when designing complex parts and ensure that the ribs are appropriately connected to increase the part’s strength. |

| Ribs should not exceed 2/3 of the wall thickness, depending on the material used. WIDE ribs may create sinking and design problems. It is typical for a design engineer and plastic manufacturer to core out some fabric to reduce shrinkage and keep the strength. | |

| If the height of the ribs exceeds 3 times the wall thickness, this could result in the part being short/unable to be filled. Rib placement, thickness, and length are critical factors in determining the viability of a part in its early design phases. | |

| Gate | In a mold part, a gate is a point at which liquid plastic flows into it. Injection molded parts have at least one gate, but they are often produced with multiple gates. Runner and gate locations influence polymer molecules’ orientation and how the part shrinks during cooling. As a result, gate location affects your part’s design and functionality. |

| The gate should be placed at the end of a long and narrow part if it must be straight. It is recommended to have a gate positioned in the centre of parts that must be perfectly round. | |

| With the input of your plastic manufacturer team, you will be able to make optimal decisions regarding gate placement and injection points. | |

| Ejector Pin | Mold ejector pins (located on the B-side/core of the mold) are used to release plastic parts from a mold after being molded. The design and positioning of ejector pins should be considered as early in the process as possible by plastic manufacturers. This is even though they are usually a relatively minor concern in the early design phases. Indentations and marks can result from improperly placed ejector pins, so proper placement should be considered in the early phases. |

| Ejector pins are typically located at the bottom of side walls, depending on the draft, texture, depth, and type of material. You might be able to confirm that your initial ejector pin placement was correct by reviewing the design. In addition, you may be able to make further changes to improve production outcomes. | |

| Sink | Sink marks can appear on the injection molded plastic part during injection moulding when the material shrinks more in thicker areas such as ribs and bosses. In this case, the sink mark is caused by thicker areas cooling slower than thin ones, and the different cooling rates lead to a depression on the adjoining wall. |

| Sink marks are formed due to several factors including the processing method, the geometry of the part, the material selection, and the tooling design. The geometry and material selection of the part may not be able to be adjusted based on its specifications, but there are several options to eliminate sink areas. | |

| Sinking can be influenced by tooling design (e.g., cooling channel design, gate type and gate size), depending on the part and its application. The manipulation of process conditions (for example, packing pressure, time, phase of packing, and conditions) can also reduce sink. Further, minor tool modifications (e.g., foaming or gas assist) can reduce sink. It is best to consult your injection molder and plastic manufacturer regarding the most effective method to minimize sink in injection-molded parts. | |

| Parting Lines | For more complex parts and/or complex shapes, it is important to note where the parting line is located. |

| Having your design shared with your injection molder can greatly influence your finished product’s production and functionality since designers and molders tend to evaluate parts differently. The challenge of parting lines can be addressed in several ways. | |

| It’s important to be aware of the importance of the parting line when designing your initial concept, but you are not limited to that. You may be able to locate other possible locations using CAD software and mold flow analysis. When you work with an injection molder, they keep your part end use in mind and help you determine where the parting lines should be placed. | |

| Special Features | It is essential to design plastic parts so that mold tools can open them and eject them without difficulty. Injection molds release parts by separating the two sides in opposite directions. A side action may be necessary in some instances, where special features such as holes, undercuts, or shoulders prevent the release from occurring. |

| Coring is pulled in a direction opposite that of mold separation as a side action. In some cases, costs may increase due to this flexibility in part design. | |

| When designing and developing a product, you (plastic manufacturers )were having the right injection molder, and engineer on your side is essential. You can avoid many issues by working with them. In integrating these elements into your product design process and working with a plastics engineer who has experience with these materials, your goal will be to get your product to market as quickly and cost-effectively as possible. |

How to use low-volume injection molding

Manufacturing a multitude of identical parts with injection molding is marvelously useful. Hardened metal molds cost a lot to tool, so it is necessary to produce large quantities to make the project cost-effective.

Today, rapid injection molded parts can be created in smaller quantities by using advanced manufacturing processes and technologies, as well as efficient bridge tooling solutions. Topworks strives to be more efficient in everything we do.

From design and prototyping to post-production and fulfillment, we are committed to working directly with our customers to deliver high-quality, affordable parts in a speedy manner. Let us help you make your dream a reality.

We are committed to going in for high-quality, cost-effective parts in a speedy way. By utilizing our expertise in rapid injection molding and efficient bridge tooling solutions, we can help you reduce your production costs to reap huge fruits while providing you with the highest quality products on time.