As someone who has founded and worked as an experienced engineer within an Injection Molding Business for over 15 years I intend to shed some light on a relatively unknown yet invaluable industry- Custom Injection Molding.

What is Custom Injection Molding?

To describe the undertaking of injection molding is simple – we produce parts en masse by injecting molten material into a mold that takes the desired shape once it cools down.

Conversely. The custom injection molding business crafts individual and unique items based on specific. Carefully curated customer requests. However,One significant issue often faced by new clients is misunderstanding how pricing works in this sector. Regrettably when initial meetings between clients and their custom injection molding suppliers take place – cost estimations are frequently skewed.

The Cost Factor in Custom Injection Molding

Unintentionally undervaluing costs per unit production or assembly owing to assuming producing one or a minimal quantity will proportionally decrease the overall cost of production.

One time costs paid upfront for creating molds can be considerably more expensive than any other part of the manufacturing process- and demands high levels of skill with precision machining. When manufacturing small volume levels and niche prototype products- mold creation costs stay constant while demand decreases which increases unit price averages compared to other forms of manufactured goods.

Custom injection molding provides unique and perfect fit solutions to create something from scratch that already exists in someones’ head or wish list but will require expert craftsmanship to actualize at higher price point average rates per unit scale in small volume requirements/models compared 0.1$/per unit for mass productions.

The Power of Mass Production in Injection Molding

That is where injection molding’s power of mass production shines: once a mold has been designed and produced parts can be produced quickly and cost effectively – with material costs per part typically being minimal while labor costs spread among several units, thus leading to decreased per unit costs with larger order volumes.

Compare purchasing one bag of chips at a convenience store versus buying an entire box from wholesale retailer: at wholesale retailers, each individual bag costs significantly less because their manufacturing, packaging and shipping expenses have been spread among many more products in one box.

Understanding Injection Molding By understanding all aspects of custom injection molding, customers can make more informed decisions. Businesses should weigh the benefits and drawbacks of customization against cost considerations when considering these decisions; on one hand custom parts provide differentiated products while initial costs could be higher.

Conclusion The custom injection molding industry can produce unique, high-quality parts at competitive costs; to maximize this advantage it’s wiser to order larger volumes than ordering individually. As in any industry, knowledge and understanding are the keys to making informed, cost-efficient decisions.

Let’s dive deeper into what suppliers must provide accurate quotes in custom injection molding industry.

The Necessity of Detailed Information for Accurate Quoting

Clients seeking custom injection molding often approach suppliers with only an image or photo as part of their request for quote. While this might appear sufficient for an untrained eye, suppliers require much more detail in order to offer accurate quotes.

Imagine trying to bake a delicious cake using only an image as your guide; without knowing details such as flour type used or quantity of butter needed or temperature/time requirements for baking it is unlikely that your finished masterpiece resembles what is depicted on its photo! This analogy illustrates why detailed information regarding injection molding needs must be provided accurately for optimal production results.

What Detailed Information Should You Provide?

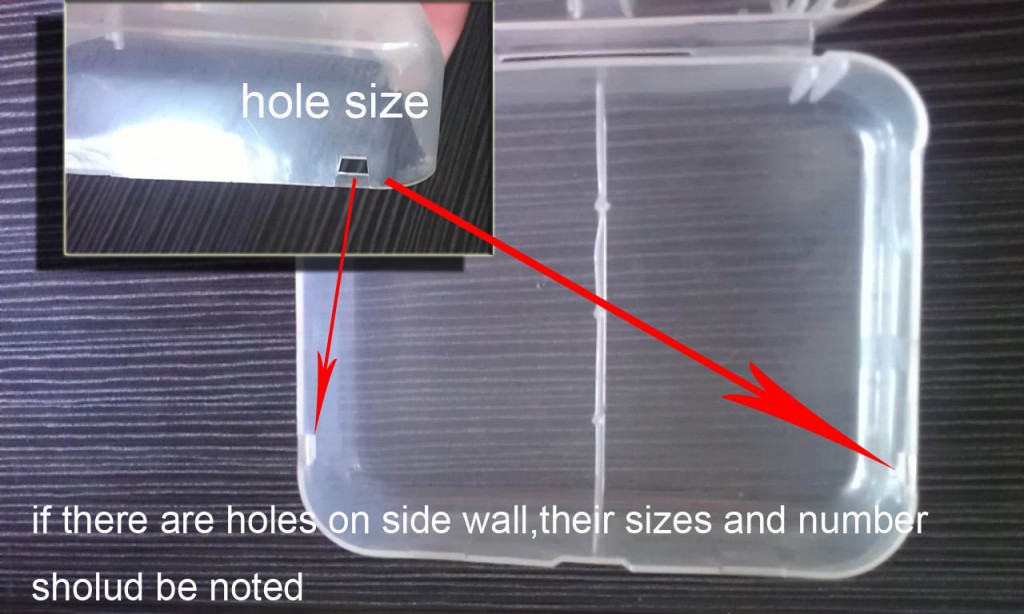

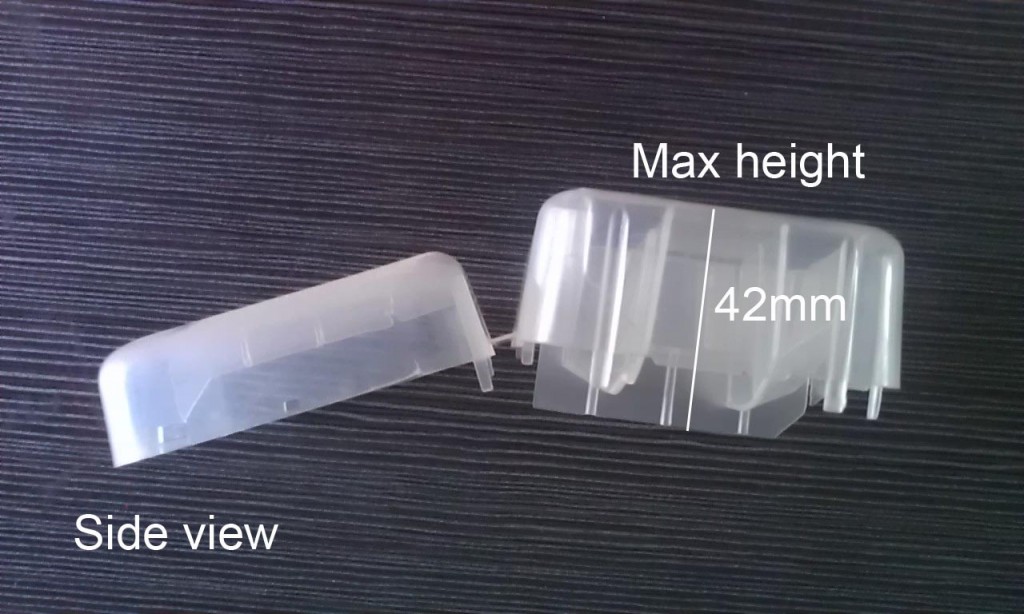

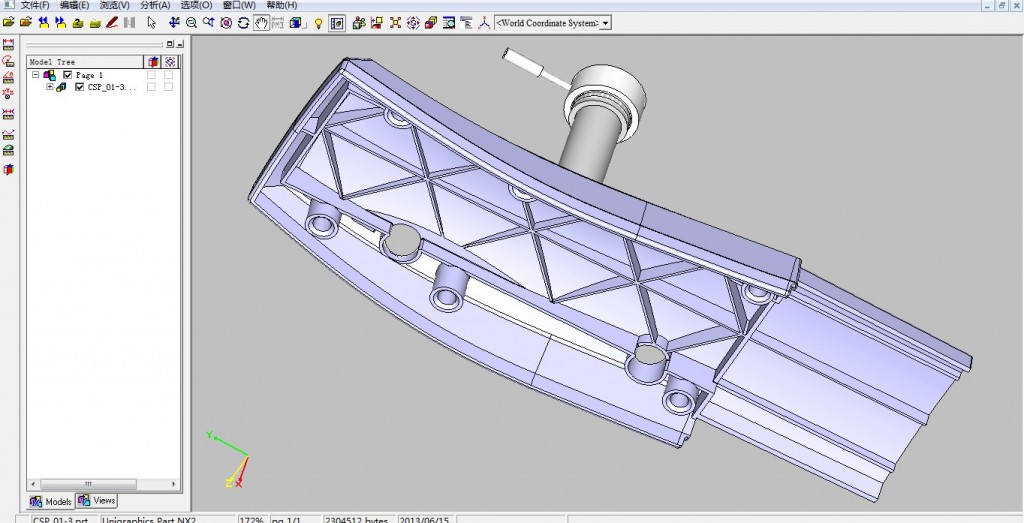

Suppliers require high-quality photographs from various angles that capture your product in order to offer an accurate quote. Think of taking passport photos where all details of your face must be visible from front view – in much the same way, having multiple views from different perspectives of an object allows a more precise assessment of its complexity and work required in recreating it.

Not only should these photos highlight specific product features like holes or recesses; dimensions should be clearly noted; it would be extremely beneficial if weight can also be provided; all this helps determine material costs and complexity of mold design.

The Power of Comprehensive Information

Just as following an intricate recipe helps produce an ideal cake, providing accurate product data helps suppliers in custom injection molding to produce parts precisely to your specifications – and provide more precise quotes, decreasing any surprises down the line.

While one picture may tell a thousand stories, in custom injection molding more is said by adding multiple photos with specific details that help customers and suppliers understand exactly what it will take to recreate a product accurately – which enables effective communication, expectation setting and cost estimating between customers and providers alike. Providing more details will likely produce better outcomes!