In today’s highly competitive manufacturing environment, accurate injection mold cost accounting and swift quoting capabilities have become crucial factors in a company’s competitiveness. To meet this demand, an intelligent material cost calculator has emerged, not only significantly improving work efficiency but also substantially reducing human error, providing reliable data for business decision-making.

Rectangular Steel Material

| Length (mm) | Width (mm) | Height (mm) | Density (g/cm³) | Unit Price ($/kg) | Volume (cm³) | Weight (kg) | Total Price ($) |

|---|---|---|---|---|---|---|---|

| 0.00 | 0.00 | 0.00 | |||||

| 0.00 | 0.00 | 0.00 | |||||

| 0.00 | 0.00 | 0.00 | |||||

| 0.00 | 0.00 | 0.00 | |||||

| 0.00 | 0.00 | 0.00 | |||||

| 0.00 | 0.00 | 0.00 | |||||

| 0.00 | 0.00 | 0.00 | |||||

| 0.00 | 0.00 | 0.00 | |||||

| 0.00 | 0.00 | 0.00 | |||||

| 0.00 | 0.00 | 0.00 | |||||

| Rectangular Steel Total | 0.00 | ||||||

Cylinder Calculation

| Diameter (mm) | Height (mm) | Density (g/cm³) | Unit Price ($/kg) | Volume (cm³) | Weight (kg) | Total Price ($) |

|---|---|---|---|---|---|---|

| 0.00 | 0.00 | 0.00 | ||||

| 0.00 | 0.00 | 0.00 | ||||

| 0.00 | 0.00 | 0.00 | ||||

| 0.00 | 0.00 | 0.00 | ||||

| Cylinder Steel Material Total | 0.00 | |||||

Additional Costs

| Item | Amount ($) |

|---|---|

| Sliders | |

| Lifters | |

| CNC | |

| EDM | |

| Wire Cutting | |

| Polish/Texture | |

| Labour Cost | |

| Mould Components | |

| Trial Out | |

| Others | |

| Total Cost | 0.00 |

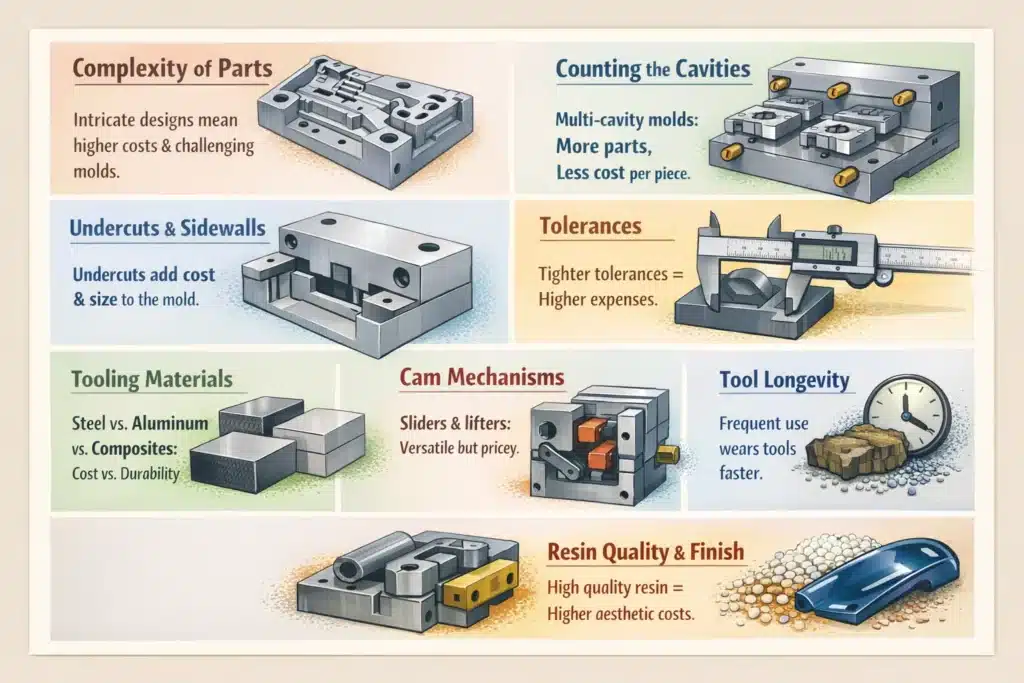

The core functionality of this injection mold cost calculator revolves around two common industrial material shapes: cuboids and cylinders. For cuboid materials, users need only input length, width, height, density, and unit price, and the system automatically calculates volume, weight, and total price. Similarly, for cylindrical materials, entering diameter, height, density, and unit price yields corresponding calculation results. This design fully considers the most common material shapes in manufacturing, making the injection mold cost calculation process more aligned with practical needs.

A highlight of the calculator is its real-time update feature. Whenever a user modifies any parameter, the system immediately recalculates and displays the latest results, greatly enhancing work efficiency, especially in scenarios requiring frequent parameter adjustments. Moreover, the injection mold cost calculator offers multi-row input functionality, allowing simultaneous calculation of materials with various specifications, which is particularly useful for cost estimation of complex projects.

Beyond basic material costs, this calculator also takes into account various additional costs in the manufacturing process. Users can input extra expenses such as ejector pins, lifters, CNC machining, EDM, wire cutting, polishing/texturing, labor, parts, mold trials, and more. Consideration of these details makes the final cost estimate more comprehensive and accurate.

Another important feature of the injection mold cost calculator is its clear structure and intuitive interface. It displays cuboid materials, cylindrical materials, and additional costs in separate tables, with a grand total at the end. This design not only facilitates user input and data viewing but also aids in comparing and analyzing different cost components.

In practical applications, this calculator can significantly improve quoting efficiency and accuracy. For instance, when receiving a customer inquiry, sales personnel can quickly input the required material specifications and quantities, add estimated processing costs, and provide a relatively accurate quote within minutes. This not only enhances customer satisfaction but also wins more business opportunities for the company.

Overall, this smart material injection mold cost calculator is a product that combines traditional manufacturing knowledge with modern information technology. It simplifies the cost accounting process, improves work efficiency, and provides more accurate cost information for management, aiding in the formulation of more competitive pricing strategies and wiser operational decisions. As the manufacturing industry trends towards intelligence and digitalization, such tools will undoubtedly play an increasingly important role.