Hey there chair manufacturers! Have you heard about the amazing chair mould service coming straight from China?

I know you’ve probably spent forever trying to find high-quality chair moulds that meet your specific needs. The search is over! These guys provide a one-stop shop for all your chair mould requirements. I’m talking unbeatable quality and service that’ll blow your mind.

“I’m glad to inform you that all plastic parts are perfect!!! We are delighted, and therefore there are good chances to continue our relationship for any coming new project.”

CRISTIANO

ITALY

“Steven is a very detail-oriented project manager and engineer who can solve problems creatively and also provides excellent service. It was a pleasure working with him.”

DAVID

USA

No more dealing with multiple confusing suppliers or getting stuck with moulds that just don’t cut it. This team handles everything from start to finish – smooth sailing all the way. highest standards before they even reach you. That means total peace of mind that your finished chairs will be amazing.

Why settle for ho-hum chairs when you could be making extraordinary ones? Their moulds are crafted to produce chairs with insane comfort and killer looks. Just imagine the reactions when people see your cutting-edge chair designs in person!

The best part is you can count on flawless quality control. These pros meticulously inspect each mould to guarantee they’re up to the

This is your chance to take your chair business to the next level! Stay ahead of the competition with these game-changing moulds. Just watch those sales grow when you start offering incredible chairs people actually want.

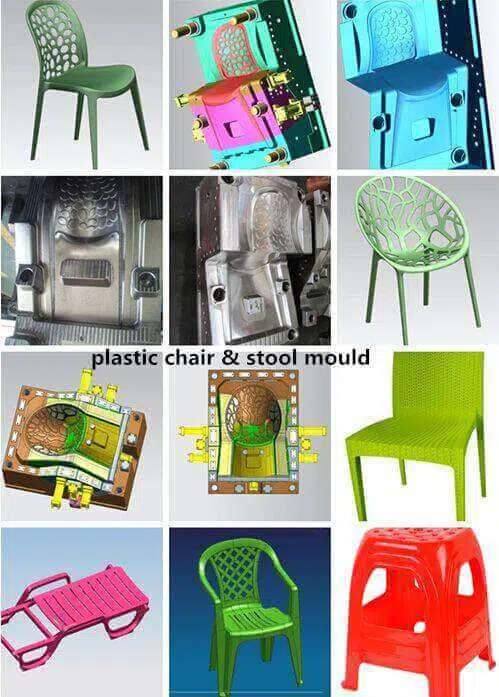

Optimizing Plastic Chair Manufacturing with Quality Injection Chair Molds

Plastic chairs have become ubiquitous in modern furniture for their durability, customizability, and cost-effectiveness in mass production. As a top Chinese manufacturer of injection molds specifically engineered for plastic chair production, we understand what chair producers need to maximize output while minimizing overhead expenses.

Our injection chair molds offer key advantages to significantly improve the efficiency, consistency, and flexibility of your plastic chair manufacturing operation.

Durability for Extended High Production Volumes

Our specialized injection molds for chairs are crafted from premium materials like 718 P20 steel . Compared to lower-grade molds, our molds offer superior heat conduction and dimensional stability across long production runs with heavy use.

The high durability and longevity of our molds enable chair producers to achieve exponentially higher production volumes over years-long time scales before maintenance and replacement is needed. With exceptionally hard-wearing molds built to withstand rapid injection cycles, our customers cut down on mold maintenance expenses and equipment downtime.

Precision Engineering for Consistent Output Quality

Injection molds built with back inserts variations will result in chairs that deviate from specifications. Our skilled engineering team uses precision computer-aided manufacturing (CAM) and quality assurance protocols to fabricate molds to fine tolerances.

Key design elements in our molds such as cooling channels, ejector pins, and runner dimensions are carefully controlled to enable the consistent, high-quality output of plastic chairs from your production line. The dimensional stability and precision craftsmanship of our molds translate directly to less variance in your chair products.

Diverse Customizability

We work directly with chair producers to understand aesthetic, structural, and functional priorities in chair molds. Leveraging expansive in-house expertise in mold design, engineering, and machining, we can customize molds to accommodate:

- Detailed surface textures and patterns – from smooth, gloss finishes to textured surfaces

- Ergonomic shapes and contours – forms that provide lumbar support, encourage healthy posture, and maximize comfort

- Multi-material capabilities – for overmolding soft tactile elastomers onto rigid structural plastic,like PRT,PP and PC.

Whether producing modern chrome chairs or cozy textile-lined designs, our adaptable injection molds support diverse custom chairs that align with your brand and vision.

Key Services for Turnkey Mold Development

- Rigorous engineering studies of product design

- Custom mold design focusing on quality, efficiency, and precision

- CNC machining of mold components and sub-assemblies

- Precision grinding and finishing to refine chair mold tool surfaces

- Assembly and testing using stringent quality control standards

- Final inspection certification before delivery

At every step, our team leverages design for manufacturing (DFM) best practices tailored to injection molding production of plastic chairs. We provide turnkey mold development from initial concept designs to certified, production-ready molds formatted for your specific machinery.

Affordable Pricing for Production Scale Needs

We understand the slim profit margins chair producers operate within and price our molds affordably. Compared to European or American suppliers, our manufacturing and labor costs are highly competitive while still delivering outstanding quality.

For high-volume production runs, the potential savings and increased efficiency quickly offset our affordable mold pricing. We also offer discounts for bulk and repeated orders.

Ensure Success With Our Injection Chair Molds

Investing in the right injection molds is critical for profitable, efficient plastic chair manufacturing. As a leading Chinese manufacturer specializing in high-quality chair molds, our products enable major upgrades across your production line.

Key Benefits

Our customers report numerous bottom line gains after integrating our molds:

- +10% production output per year

- -20% variance in chair quality

- +15% faster cycle times

- -25% mold maintenance costs

By driving significant increases in throughput and decreases in scrap, our precise injection molds quickly pay for themselves many times over through expanded production capacity over years of use.

Ideal For High Volume Production Lines

Engineered to excel in rapid, high duty cycle injection processes, our molds are ideal for manufacturers producing:

- Over 20,000 chairs per year

- Output volumes requiring overnight production

- Multiple continuous shifts per day

- Frequent molding machine changeovers

Premium materials enhance thermal endurance so our molds stay dimensionally stable during months of sustained, high-throughput operation.

Leverage Our Extensive Expertise

With over 20 years experience manufacturing specialized injection molds, our seasoned team of over 50 engineers and technicians has unrivaled expertise in designing chair molds optimized for plastic manufacturing. We provide extensive technical consultations to identify key requirements for your production environment and chair models.

Whether you require rapid prototype molds for evaluating part designs or durable long-run production molds churning out thousands of identical chairs annually, we deliver the ideal mold solution engineered for your needs.

Partner With Us for World-Class Chair Molds

Simplify plastic chair production and maximize manufacturing productivity with our high-end injection molds built to drive efficiency. We offer in-depth engineering support tailored to your production environment and chair models.

Contact our application engineers today to discuss how upgrading to our molds can significantly benefit your bottom line through expanded capacity, lower scrap, and reduced overhead expenses.