Why Make Plastic Injection Molds in China?

Many people assume that Chinese plastic injection molds are going to be of poor quality. However, a huge number of companies- including multinational corporations- still choose to buy such molds. Does that mean these companies are naive or making a mistake? Of course not. In fact, Chinese injection mold manufacturers can make some of the best molds on the market- for a much lower price than European and American companies can offer.

Across China, the plastic injection mold manufacturing industry is growing from strength to strength. Not only do they have the skills required to make superior injection molds, but they also possess excellent English skills. That extends into the marketing departments, too- most Chinese mold sellers have a strong grasp of CAD drawing and the capability to choose the right materials. This allows them to speed up the communication process between partner engineers and the customer.

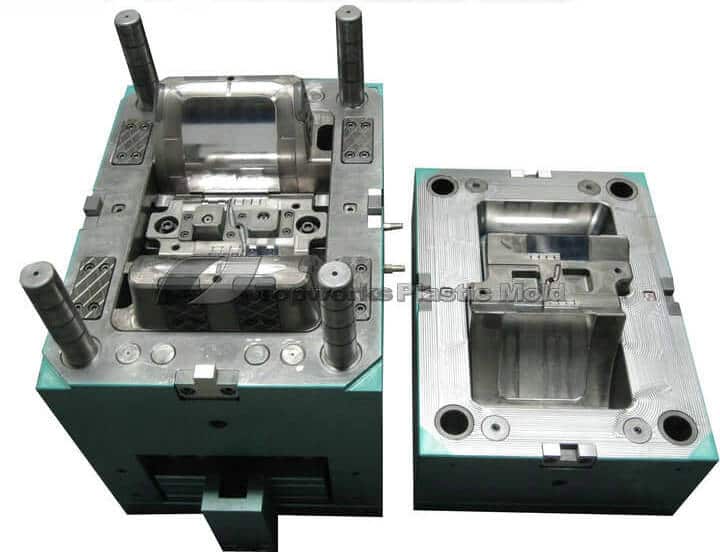

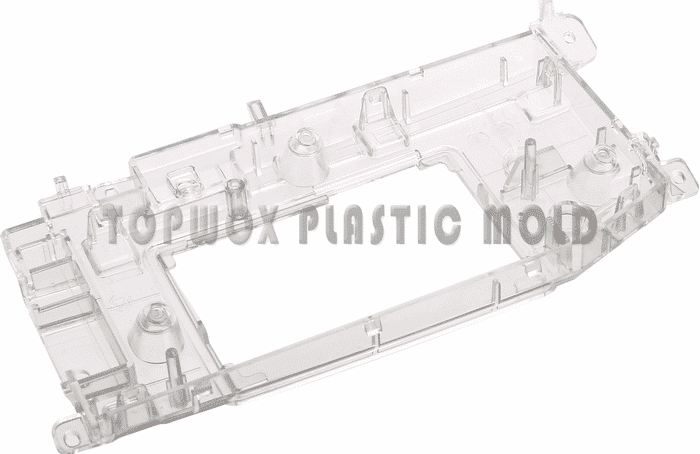

When making a brand-new plastic injection mold, the process usually starts with a 3D drawing of the product. Using that drawing, engineers can then decide how to make the mold, thinking about things like the size and structure of the mold, the material, and how to keep the cost as low as possible- all while keeping the customer’s requirements in mind. Our factory has worked with multiple European and American companies for many years now, so all you need to do is send us your drawings- we’ll be happy to carry out a test to show you what we have to offer.

Mold manufacturing has been around in China for over 30 years, meaning plenty of high-quality manufacturers are operating today. Many possess the same skills and experience as their western counterparts. While they may only be paid around 60% of what they could make doing the same job in the US, they will still produce top-quality molds that you can really rely on.

How should I go about choosing a Chinese injection mold supplier?

The main reason why so many US and European clients come to China for plastic injection molds is that they are much cheaper to make here. However, price shouldn’t be the only thing you look at; you should also consider the following to be sure that your chosen company is going to do a thorough job when making your mold.

- References from past clients

- Quality of tool steel used

- Standard of their factory and equipment

- Quality control and validation processes

- Experience- ideally, you’ll want a company that really knows what they are doing

- Capability- will they be able to handle the whole project in-house or outsource parts of it

- Current capacity

- Are they able to properly serve international clients?

How can I find a good Chinese mold maker?

There are a huge number of mold makers across China, so you must make the right decision when choosing one. This can sometimes take quite a while, but all that effort is worth it in the long run. But while it’s easy to find well-known mold shops in the western world, in reality, things aren’t that much harder in China. All you need to remember is that low prices are usually low for a reason- because they compromise on quality. Getting a good quality mold is more important than a cheap one, so attending a mold trial is a smart idea. If the cost of traveling to China is too high, then a sampling video is always an option, too.

You are also strongly advised to read through the terms and conditions provided with each quote, and vitally, the warranty clauses. Chinese mold quality is always improving, but as a customer, you’ll still need to carefully supervise the design and manufacture process to ensure that you’re getting exactly what you need.