PET Preform Mould Manufacturer (China)

High-cavitation PET preform moulds engineered for stable cycle time, consistent neck finish, and long mould life. Built to reduce your Total Cost of Ownership (TCO) — not just the initial tooling price.

- Preform weight range: 8g–120g (custom)

- Neck finishes: PCO / 1881 / 1810 / 29/25 (custom)

- Cavities: 1–96+ (project-based)

- Gating: Valve gate / Hot runner

Best results with preform drawing + neck finish + target weight + resin/IV + annual output + your hot runner preference.

Typical Project Targets

Good Fit If You Need

- Consistent neck finish for high-speed blowing lines

- Stable cycle time & predictable output planning

- Long mould life with controlled maintenance risk

- Clear scope: hot runner, spares, validation deliverables

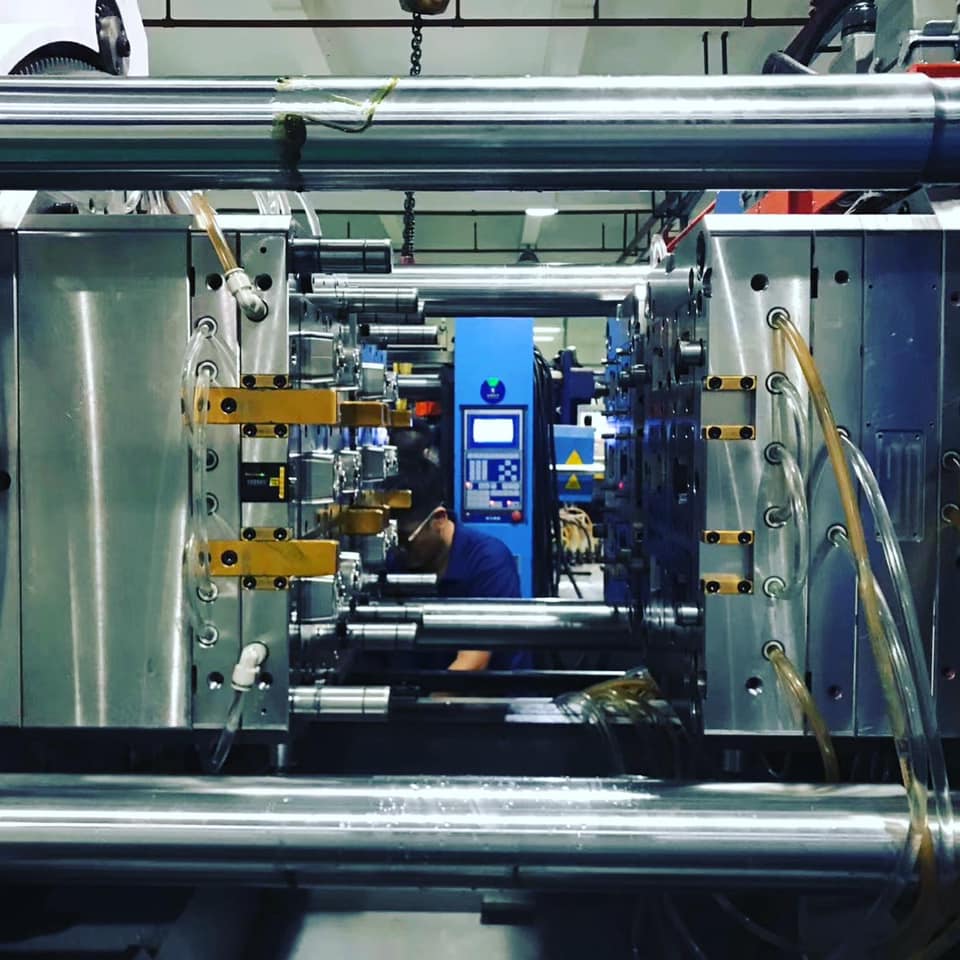

Video: PET Preform Mould in Production

Visual proof of stable output and mould performance—useful when comparing suppliers beyond tooling price.

Product Overview

PET preform production is driven by repeatability: neck finish accuracy, preform weight consistency, and thermal balance. Our moulds are designed for stable production windows—reducing scrap, downtime, and cost per preform over the full lifecycle.

Preform Specification Coverage

Share your neck finish standard and target preform weight. We align mould layout, gating, and cooling to your resin/IV, output requirements, and blowing line compatibility.

Neck Finish Control

Critical dimensions and sealing surfaces are treated as “must-hold” zones to ensure cap fit and leak prevention.

Weight & Wall Consistency

Cavity balance and process window validation help keep weight variation and defects under control for stable blowing.

Output Planning

Cavitation and cycle-time targets are designed together—so your total output matches annual demand with predictable uptime.

Typical Applications

Engineering & Mould Design Highlights

Thermal Balance for Stable Cycle

Balanced cooling reduces hot spots and shortens cycle time while maintaining consistent preform geometry.

Valve Gate & Flow Control

Hot runner + valve gate solutions are selected to support consistent filling, reduce gate defects, and improve repeatability.

Wear Strategy & Long Mould Life

Wear-critical areas are designed for durability and serviceability to reduce downtime and protect long-term output.

Low Tooling Price vs Lower Total Cost of Ownership (TCO)

In PET preform production, the real cost is driven by stable cycle time, controlled scrap, and reliable uptime. Compare quotes with a production-first view—not only the invoice price.

Real tooling details matter for uptime and scrap control—key drivers of TCO in high-cavitation preform production.

Quote A: Lowest Price

- Cooling design simplified; thermal imbalance risk

- Limited validation; narrow process window

- Higher risk of neck variation, short shots, stringing

- Maintenance shows up earlier in production

Quote B: Optimized for TCO

- Balanced cooling for stable cycle time

- Hot runner/valve gate matched to your resin & output

- Defined scrap assumption + measurement at trial

- Serviceable wear areas to reduce downtime

Procurement Questions to Ask (Copy & Paste)

Options & Customization

Hot Runner Brand Options

Mold-Masters / Husky / YUDO / or your plant standard (project-based).

Cavitation & Layout

From prototype to high cavitation—designed around output, press capability, and uptime targets.

Spare Parts Package

Recommended spares list available to reduce unexpected downtime in mass production.

Quality, Validation & Deliverables

Trial Report

Sampling results, key dimensions, and stable parameter recommendations to support mass production ramp-up.

Inspection Approach

Critical dimensions (neck finish zones) can be verified using fixtures/CMM based on project requirements.

Scope Clarity

Clear inclusions/exclusions for hot runner, spares, electrodes, and validation to prevent quote confusion.

What We Need for an Accurate Quote

Send the details below to receive a fast, comparable tooling proposal aligned to your output plan and TCO targets.

- Preform 2D/3D + neck finish standard (PCO/1881/1810/29/25, etc.)

- Target preform weight, resin & IV (and any additives)

- Required cavitation and annual output target

- Hot runner/valve gate preference (if any)

- Critical dimensions & inspection requirements

- Machine/press info (if available): tonnage, tie-bar, available stack height

Fastest Way

Share files + requirements, and we’ll reply with tooling concept, lead time, and TCO notes (cycle stability, scrap assumptions, scope clarity).

PET Preform Mold: FAQ

Strategic Insights: PET Preform Mold (Mould) Tooling

Built for buyers comparing suppliers on TCO: cycle stability, neck finish consistency, maintenance, and mold life.

1) What defines a high-performance PET preform mold (mould)?

A high-performance PET preform mold is built for repeatability at speed: a balanced valve gate hot runner for clean gate quality and a cooling layout designed for stable cycle time. The goal is consistent preform weight and neck finish for high-speed blowing and downstream cap fit.

2) How do you control concentricity in PET preform tooling?

Concentricity drives uniform wall thickness. We use cavity/core location control (anti-shift / self-locking features) and verify alignment during assembly and trial to reduce eccentricity risk and improve blow consistency.

3) What hot runner system do your PET preform molds use?

We commonly apply valve gate hot runner systems for PET preforms to avoid sprue waste and improve gate finish. Temperature control and balance are set up to keep melt distribution stable across cavities.

4) Can you manufacture high-cavitation PET preform molds?

Yes. We build high-cavitation PET preform molds (typical ranges include 16–144 cavities, depending on design). The focus is balance (runner + cooling + venting) so output stays stable at scale.

5) What steels/materials do you use for long mold life?

For PET preform cavities/cores, we typically use corrosion-resistant, polishable tool steels (e.g., S136 class) with proper heat treatment and surface finishing to support long service life and optical clarity requirements.

6) How do you achieve faster cycle time in PET preform molds?

Cycle time is mainly driven by heat removal. We optimize cooling channels near gate/neck regions and critical thickness zones, and select insert materials/structures based on the preform weight, wall thickness, and required clarity.

7) Why are interchangeable inserts important in PET preform tooling?

Fully interchangeable cavity components simplify maintenance: you can replace a single cavity set instead of pulling the full mold. This reduces downtime and helps keep production predictable for high-volume plants.