DFM and FMEA Reducing Molding Risk Probability

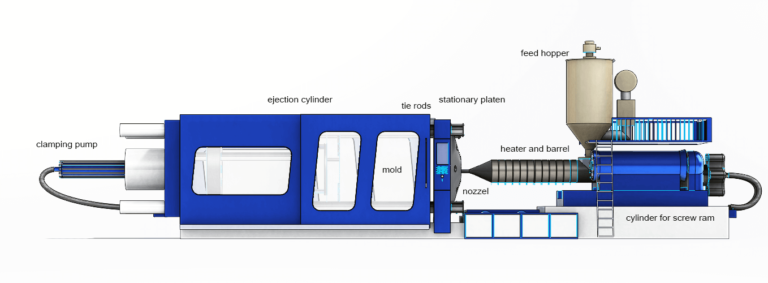

To optimize entire injection molding manufacturing process, Design for Manufacturability (DFM) is recognized as an effective approach that integrates engineering and production during the plastic design stage to yield high-quality products that satisfy regulatory mandates at reduced cost for end-users.…