How to Manage Costs When Buying Moulds from China

Cost Management in Chinese Mould Purchases

Chinese mould purchases appeal to businesses who want high-quality products at reduced prices. Effective cost management between buying moulds from China transforms good deals into financial burdens. Finding the right balance requires knowing which items need basic quality and which require higher quality and which require a middle ground in costs. The process of cost management becomes crucial when purchasing moulds from Chinese suppliers. Here’s how it works.

Know Your Product Needs First

Your supplier search should start only after you determine exactly what you need. Your production requires a single mould or a set of different moulds. The product volume determines whether you need one mould or multiple pieces alongside the manufacturing requirements. A detailed list of specifications helps you locate both a suitable mould design along with a suitable supplier. Following this approach prevents potential money-consuming misunderstandings or errors from occurring.

Keeping an eye on quality matters more than trying to save money on a few dollars. Although low-quality molds appear as an affordable option initially, they will end up costing you more money in the future. You should focus on long-term benefits and the complete worth of the investment.

Research Suppliers Thoroughly

This part can’t be rushed. The market contains numerous suppliers who differ from each other, making it hard to distinguish them. Your first step should be researching various manufacturers. Check for customer feedback by reading reviews together with case studies and collecting testimonials. Avoid choosing the first supplier you come across. Ask suppliers for testing their products while demanding complete details about their manufacturing methods.

The price evaluation requires you to obtain multiple offers from various suppliers. That’s crucial. The diversity in your price points will enable better market insight and negotiation power during price discussions.

Factor in All Costs

Avoid concentrating solely on the mould price because hidden expenses will eventually appear. The overall costs from shipping along with taxes and customs duties and potential local warehousing expenses will become expensive very quickly. The following list presents essential elements to think about:

- The basic price for your mould constitutes its production costs.

- The transport method will be either air, sea, or land shipping. What will shipping expenses be together with the costs required to deliver the mould to your destination?

- Customs Duties and Taxes need to be factored into the total costs during Chinese imports. The costs for importing into different nations change based on the destination country.

- Before shipping from China, you should spend money on mold inspections to verify their quality matches your requirements.

- Storage fees should be included in your budget whenever you need to store moulds before their usage.

Establish a Business Partnership with Your Supply Chain Provider

The process of negotiation stands as the essential element for managing cost levels. Creating a solid connection with your supplier becomes as important as achieving price reductions during negotiations. Your supplier will grant you greater flexibility when your business relationship functions well. Your trusted supplier should offer you better prices combined with faster delivery speed and extra support during peak times.

Staying in regular contact with suppliers results in mutual benefits. Regular contact with your supplier enables quick and effective resolution in case of problems.

Think About Tooling Costs

You might need to pay for tooling expenses when you obtain the mould creation process. The cost of tooling production should be clear to you before making any decisions about the creation process. The design requires either personalized customization or standard pre-made moulds. What are the expenses for changing or modifying the mould after its production?

Knowledge about tooling expenses at the beginning enables you to prevent unexpected fees from appearing later.

Consider the Volume You Need

The number of moulds required for Chinese purchases will affect your purchasing choices. Purchasing bulk moulds will lead to discounts, yet buying additional moulds than necessary will use valuable company resources. You should purchase fewer moulds at a higher price when your order size is low in order to prevent unwanted inventory and storage expenses.

Your order volume needs to match your budget requirements to achieve the best value. Avoid increasing your required amount of moulds for lower per-unit prices.

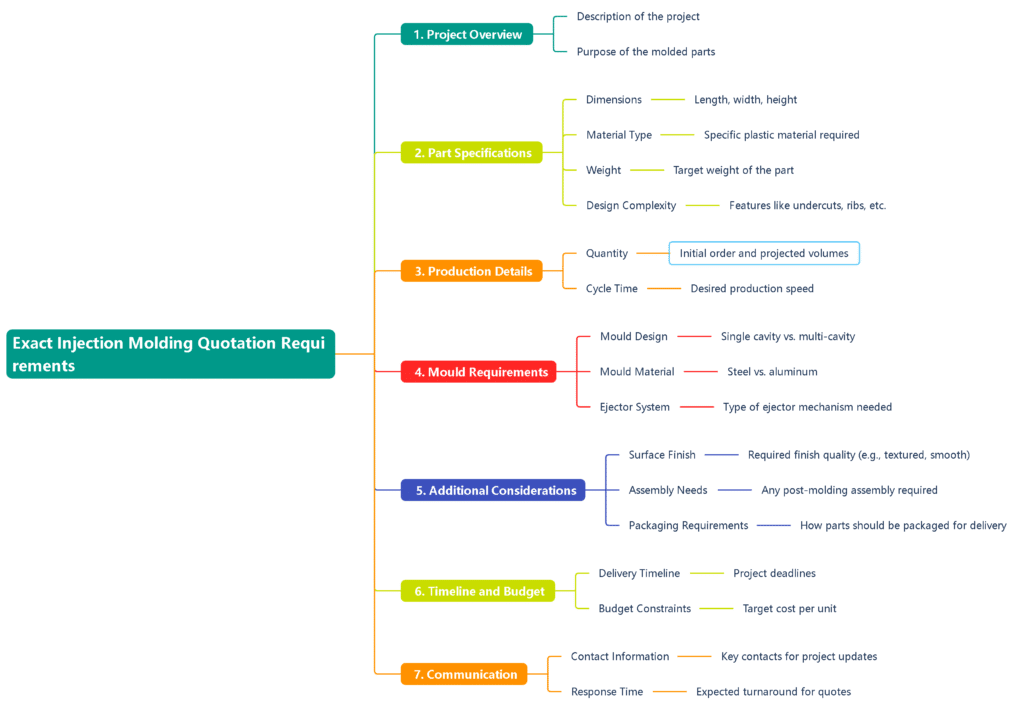

Be Clear About Specifications

Small errors in mould specifications create time wastage and additional expenses because moulds possess complex design requirements. Double-check your requirements until you reach total agreement before you sign the contract. This includes:

- You should specify what material type you require, whether it is steel or resin.

- The required precision level for the moulds constitutes tolerances.

- The design specifications include complex features that need special tools and additional work.

- Will your production require single products or multiple product quantities? Your clarity about requirements helps you find both the correct mould along with the right supplier.

The identification process requires precise definitions of materials together with necessary tolerances and design complexity levels. Getting expert advice from an industry professional or experienced individual remains a smart approach when you are unsure. The correct assessment of your needs will prevent you from purchasing substandard products that do not meet your specifications.

Compare Suppliers But Keep Quality in Mind

Different Chinese manufacturers will provide you with numerous price quotes when you request quotations. The price range among suppliers extends from extremely low to higher-end options. The lowest price should not determine your final choice in this situation. Effectively controlling costs means you must understand what each payment includes.

Low-priced moulds often result in increased long-term expenses since they usually include low-quality materials and imperfect designs. Your business will encounter manufacturing problems together with substandard products and possible production slowdowns. The cost of purchasing an excellent mould at a higher initial price often results in reduced expenses in long-term maintenance.

When searching for suppliers, request examples of their work as a standard practice. The sample review enables you to verify their work standards before moving forward with large-scale orders. Testing shoes before purchase is essential since you need to verify the fit.

Factor in Shipping and Customs Fees

Chinese mould purchases tend to focus solely on mould prices while neglecting additional expenses during the process. Your total cost will increase substantially because of shipping expenses together with customs charges and import taxes. A surprise payment at delivery time should be avoided. Before proceeding, obtain complete pricing information that includes all possible charges.

Larger orders might give you the opportunity to reach better agreement terms with your supplier. Using sea freight instead of air freight will reduce shipping costs while keeping in mind that air freight delivers products faster. Your deadline will help determine which shipping method suits your requirements best.

Contact your local customs office to understand any requirements for importing products. Your budget should include customs duties since these costs differ based on the product and the destination country.

Negotiate the Payment Terms

The start of production requires Chinese suppliers to receive payments or deposits in advance. You should try to work out payment terms that benefit your business operation. When placing significant orders, you should work with suppliers to pay only a portion upfront while you would pay the remaining balance either at delivery time or after receiving the goods.

A payment structure that allows extended time periods for payments enables better management of your financial flow. Your risk increases when you pay large sums to suppliers before delivery, especially when working with new suppliers. Before making payment to a supplier, conduct a thorough investigation of their business background and request proof from existing customers.

Avoid Over-Ordering

Large orders seem alluring because they benefit from reduced unit costs. The practice of purchasing additional moulds than your current requirements results in blocked capital and increased storage expenses. A practical approach involves starting with a minimal order to assess product quality and consumer feedback.

Your production demand growth prediction allows you to consider bulk purchases. Avoid extending your resources beyond comfortable limits when you make your purchasing decisions. The key lies in striking a proper balance because you need economies of scale but need to avoid excessive resource utilization.

Check for Hidden Costs

Suppliers may provide you with desirable mould pricing; however, they will conceal extra expenses for testing, customization, and packaging services. Getting a detailed itemized cost list from suppliers helps you stay informed about all expenses. Obtain written documentation about all aspects and confirm all conditions before starting any project.

Detailed communication functions as a critical tool during this process. Give detailed instructions about the specific product features together with quality examination protocols and delivery schedule expectations. Giving clear expectations from the start reduces the chances that unexpected fees will emerge during the project.