[language-switcher]

The gate is a narrow intersection between the main runner and the mould cavity, and the intersection is also the shortest part on the whole mold.

Its function is to make the molten plastic enter into the mould cavity quickly, which is beneficial to the rapid filling of the cavity.

After filling, the gate is condensed first to block the cavity, prevent the melted plastic from falling and avoid the pressure drop of the cavity too fast.

Insufficient backup pressure would produce shrinkage holes or dent parts on the workpiece.

Designing A Gate – Principles and Practices

There are 6main principles that need to be considered when designing an automated gate system:

- It is necessary for the gate to be set on the thickest part of the molding products, which will permit the plastic to flow progressively from thick to thin wall positions, thus controlling the loss of pressure.

- To ensure low heat losses and rapid injection of the melt plastic through the shortest, cleanest path possible, melting plastic should utilize only the shortest possible running path with the lowest amount of pressures and heat losses.

- An appropriate gate should be positioned in the part of the wall where products would be most likely to be moved easily, as well as avoiding any marks that may be created (if possible).It is important to ensure that the gate is properly positioned so that the plastic will flow uniformly in the desired direction and will aid in the flow of air.

- In setting the gate location, it is important that we avoid welding lines, monitor the important areas around the products, and avoid to compromise the strength of products.If the mold is multi-cavity, it should be designed to ensure that the gate’s size and location are controlled by the distance between the gate and the runner, and on the size of the products that will be manufactured .

- It is important to ensure that the gate is in a position that does not directly impact the thin Core, inserts, or sliders, which can potentially result in product deformation.

- The consideration when designing the gate involves the consideration of the different shrinkage along the longitudinal direction and the transverse direction.In order to ensure the same shrinkage for different cavity fillings, each melting gate of the melt must have the same pressure and temperature as it goes into the cavity.

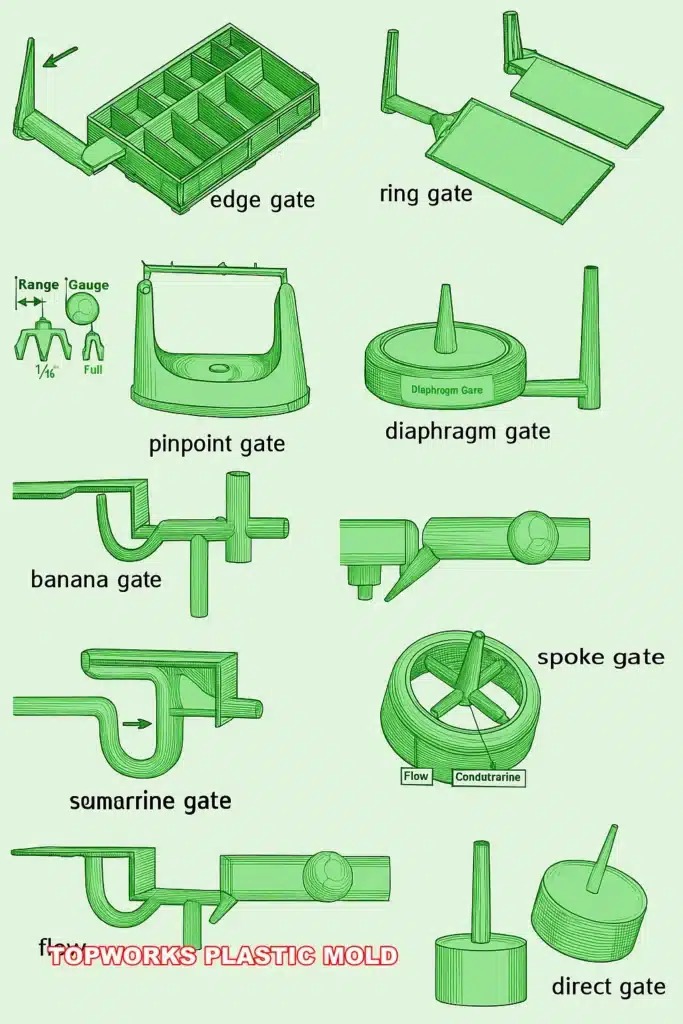

Edge gate

The edge gate represents the simplest of gate designs, it is very easy to make, and usually milling cuter can finish this job.

Although it is easy to produce, the use of edge gate is severely restricted due to poor filling.

In this case, the overall strength of the plastic product obtained is poor, and the surface finish is also not good, and the edge gate is usually used for plastic part quality requirements that are not very high, or products without the appearance requirements. In addition, it needs to cut off the gate later, which will lead to ugly scars.

Fan gate

In fact, the fan gate is an extended design of the side gate. It is used for the plastic part of a large area.

The fan gate is handed in to help reduce the warping of the product, and improve the finish of the product’s surface.In order to achieve better results,the contact area cannot exceed the cross-sectional area of the feed runner.

Due to the large size of the gate, it is difficult to remove , and the trace left is not beautiful.

Diaphragm gate

Diaphragm or disc gating can be used for cylindrical or hollow section components when concentricity and weld strength are component function requirements.

To balance mould filling,a minimum gate land length of 0.5 to 1.0mm is generally recommended. The subsequent removal of the gate disc from the moulding tends to leave a sharp jagged edge about the rim of the component.

The positioning of the gate inside the moulding serves to reduce post-mould finishing operations.

Ring gate

Ring gates are commonly employed on cylindrical mouldings when internal dimensions are more crucial than external.

A runner ‘gutter’ is machined about the mould cavity and subsequently mirrored about the core,and a land is machined connecting the gutter to the cavity wall.

Gate land depth is usually determined as a result of mould trials; shallow lands detract from the packing control of the moulding,whereas over-thick lands create degating problems and can lead to increased costs.

Spoke gate

Spoke gates can be employed on mouldings which are often too large to diaphragm or ring gate. They allow a larger volume of polymer to flow through them than either of the latter two designs.

In this case, component accuracy and weld strength are reduced in favour of volumetric throughput and packing control.

This design of gate is suitable for thicker section cylindrically shaped mouldings with high shot weights. The large gate remains usually require a machining operation to remove them after moulding.

Tunnel or submarine gate

Tunnel gating permits the automatic degating of the moulding from the feed system. The gate is sheared off the component during the ejection cycle of the moulding process.

Tunnel gate diameters vary from 0.5-0.8 mm for unreinforced plastics to larger diameters of 2 mm plus for reinforced materials.

Due to the buried design of the gate, gas trapping and the resultant burning of the moulding surface can prove a problem in use.

Bearing this in mind,adequate venting must be added to a mould which incorporates a tunnel gating design.

A gate scar is left on the surface of the moulding, which subsequently increases in size as the gate shear land wears.

Pinpoint gate

Pinpoint gates for three-plate moulds vary in size from diameters of 0.8 mm-2 mm for unloaded materials to diameters of 2.5-3 mm for loaded grades.

This design of gate also permits the automatic degating of the mouldings during use. The gate land is usually reduced in size to enable a ‘clean’ break to occur upon separation from the moulded component.

Gate breakage is achieved through pulling the runner from behind,usually by sucker or puller pins buried in the back of the runner.

As a result of reduced gate land thickness, pinpoint gates are easily damaged and tend to suffer from wear if loaded materials arc processed regularly.

Tab gate

The side filling effect of the tab gate format reduces the likelihood of jetting or worming occurring when the melt flow exits the gate.

Tab gates are frequently employed to gate large decorative mouldings such as housings or instrument cases for aesthetic reasons.

The even fill pattern produced about the tab feature serves to reduce the effects of stress-induced distortion or warpage once the moulding has solidified.

Tab features are expensive to remove from mouldings and should, therefore, be positioned in locations where they can be left on the component or have a useful function, e.g., as holding tabs for paint spraying or similar finishing purposes.

Flash or film gate

In essence, the flash gate is an extension of the fan gate .

They can all be used on flat or large-area parts. The warping of these parts is to be avoided as much as possible.

But flash gate subsequent processing will be very troublesome. Be careful when using it.