Get a quick quote from your injection molder so you can plan your budget and project. Tell them everything they need to know right away so you can get a quote.

The Significance of preliminary Design in Your acquire conclusion

In the case of first design for a product, its significance cannot be understated. A number of times, I’ve had requests for cost estimate based only from sketches. But, it’s essential to realize that even a sketch is far from a complete quote. Design units typically are measured by “mm” or “inch,” .Even a small deviation of 3 mm could be a huge difference in price. It is especially true of bigger molds that are made from costly mold steel, such as S136 costing around USD 18 for a KG as well as more costs to heat treat at a cost of USD 3.5 per kilogram.

The smallest of details on parts, for instance the sidewalls’ undercuts or holes could cause a major deviation in mold building as well as the injection molding costs. In the case of a hole, for example, the presence of a hole that is small or an undercut calls for the inclusion an automatic slide which can add a load of 10+ kilograms and needing an extra piece of manufacturing.

It is surprising that the majority of initial designs lack these vital characteristics, which often leads to a guesswork the moldmakers. Unfortunately, the guesswork usually was made based on untrue beliefs due to unclear details.

So many mold makers ignore these questions. There’s no lack of willingness to help just a lack of practical solution. Making a quote takes time and energy from a mold maker and mold makers put their time and resources into projects that are more likely to be built.

Try this: Call an injection molding tooling engineer (I’ll do it for you).

An in-person conversation with this skillful will allow you to define your needs regarding the quantity and quality of your product, an essential and extremely effective method. If you’re currently in the process of creating an innovative product, investing during the initial phase is certain to yield substantial dividends in the future.

A well-constructed foundation prior to designing will allow for faster and less costly travel.

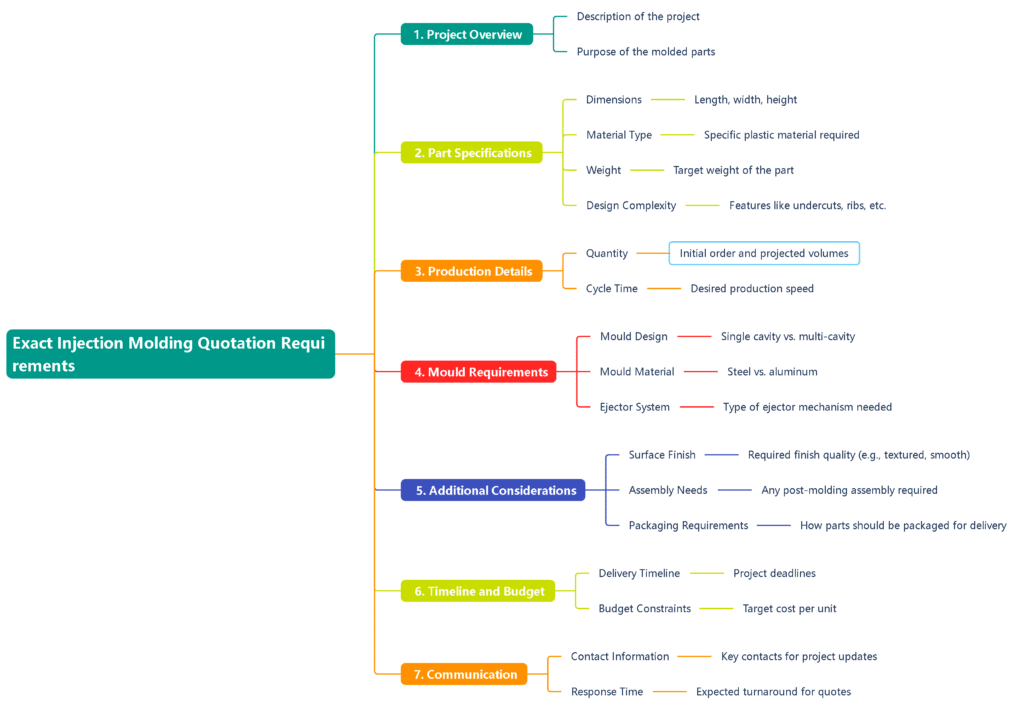

As a China plastic mold manufacturer far way from you for face to face communication, what we need to know for the mold building and injection molding requirement:

| For mold building only | Mold building & injection molding | |

| 1 | cavity | |

| 2 | plastics | plastics and its weight(unless you have 3D model) |

| 3 | Mold steel and hardness demand | |

| 4 | Quantity need to be molded | Quantity need to be molded |

| 5 | Surface Demand (mold finishing, gate demand) | Surface Demand (color, mold finishing, gate demand…) |

| 6 | Hot runner Drops | |

| 7 | Control size, assembly demand | Control size, assembly demand |

| 8 | Package | |

| 9 | Second operation (paint, print…) |

3D model could help to make a precise pricing for you ,and the software we use: solidworks,UG and Autocad .

The format we accept:

- .dwg

- .prt

- .sldprt

- .x_t

- .iges

- .stp

time and job for each part

Topworks can optimize your design for cost savings or ensure compatibility by optimizing your design before tooling. Clients are welcome to supply 3D files

Topworks can utilize Computer Numerical Control (CNC) to produce a machined prototype or 3D printing that you can see and feel to validate the design of your part.Also we supply vaccum casting service

During this stage, your Tooling Information Worksheet is used to design the tool.

The accuracy of the tool design is validated.

The tool is precisely fabricated according to the validated design using Computer Numerical Control (CNC), and Electrical Discharge Machining (EDM) …

The first test shots will be sent via courier soon after the injection molds are made. Once sent, these usually arrive in 2-5 days.

At this point, Topworks makes any changes to the tool that is necessary to bring it into compliance with the approved specifications. Topworks makes any changes that are necessary (specifically excluding design changes, which are always charged for) free of charge.

In this stage, the texturing process is done, which is usually the last step before mass production.

Topworks side

In this stage, the tool is handed over to the customer or ready for injection molding.

The right injection molding estimate takes some effort ,however it’s well worth the effort! Begin by sending your provider details of the information about your design – drawing CAD, the type of resin the quantity required, and so on. The more precise information you focus on providing in advance ,the more precise their estimate is likely to be.

Consider the bigger plan, including timelines, or other services that are required. Draw everything out in a way that your vendor is aware of the entire extent of the project right at the beginning.

This is the most important aspect suitable asking questions! If you’re uncertain about anything in particular, including the material you choose or your production capability you can inquire. The perfect supplier will be able to respond to all of your questions in a clear manner and without making you feel guilty to ask.

Make sure you do your homework in order to locate the perfect injection molding company. It is important to find a partner who has created products similar to the ones you are with before and have glowing reviews of high-end service and quality. Finding the perfect match, your project will go much more efficiently.

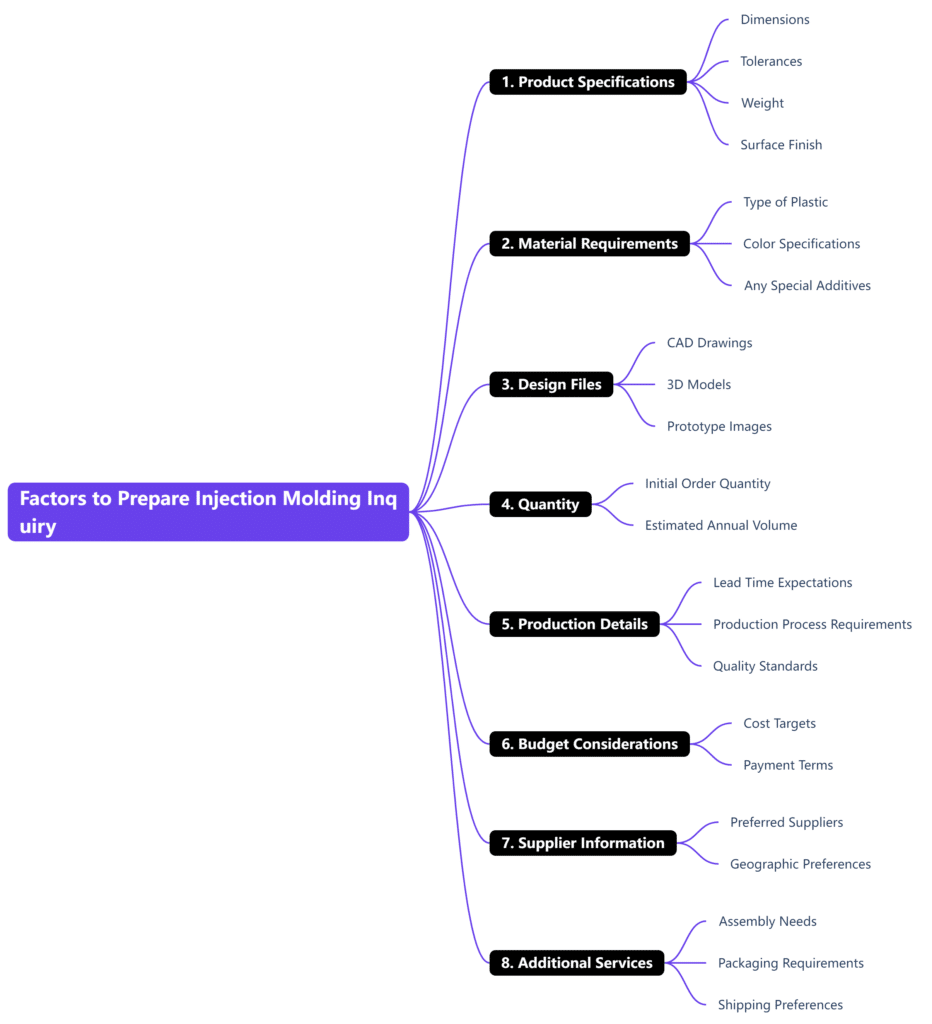

1. Prepare your part details:

- Drawings in CAD: Include drawings in both 2D as well as 3D CAD files in standard formats such as .pdf, .stl, .igs and .step. The files must clearly show the dimension of the piece, surface finish, tolerances as well as any other special characteristics.

- Physical samples In the event that the CAD files are not available Send physical examples of the part you want together with clear annotations.

- Material specifications: Indicate the specific type and quality of plastic resin you want. If you aren’t sure, ask the supplier to get recommendations in relation to your component’s use and requirements for performance.

- Part Quantity: You must indicate the approximate number of components that you will require. Production quantity is a major factor in the quote process.

2. Define your project requirements:

- Timeline for your project: Provide expectations for deadlines and deadlines you expect to turn around.

- Needs for mold: Indicate whether you require a brand new mold or if you plan to build one together an existing mold.

- Other services: List the more requirements you require like prototypes, finishing, assembly packaging.

3. Communicate clearly and concisely:

- Be specific in your descriptions. Do not assume that your vendor understands each aspect of your piece or your project. Define the purpose as well as its functionality and particular aspects to be considered.

- Be sure to ask questions that are relevant: Don’t delay in addressing any concerns that you may have regarding the quote process, options for material or any potential issues.

- Be prompt in responding to all requests made by your supplier promptly so that you don’t experience delay.

4. Choose the right supplier:

- Know-how and experience: Pick an expert supplier who has proven expertise of producing similar parts to your own.

- Reputation and certificates: Look for companies with a good name for reliability, quality as well as compliance with applicable standard industry practices.

- Customer service and communication Select a vendor who responds quickly to your needs, communicates effectively and is able to understand the needs of your customers.

Tips to Simplify the Mold Buying Process

Buying a mold is hard, but sticking to these guidelines will make it much easier. These aren’t hard and fast rules but very important for mold makers of all kinds.

1. Detailed RFQs Get Accurate Quotes

To effectively communicate your needs to your customer you must submit a Request for Quotation (RFQ) that leaves no room for guessing. Include specifics like type of mold, number of cavities, preference for steel, expected life of the mold and any warranties. If you are unsure ask your moldmaker to help you determine the best mold for your specific needs. The more detailed your RFQ the more accurate the quote you will get.

2. Be Transparent in Your Request for Quote

Be clear about the reason when requesting a quote. If you’re looking for a rough estimate for your marketing needs state your intention. Don’t ask for a full engineering analysis for a project that’s years down the road. Mold makers invest time and energy in quotes that have promise so make sure you’re comparing your needs with real potential customers.

3. Respect Intellectual Property

Respect the intellectual property of mold makers which includes their experience and ideas. Be discreet when requesting quotes and don’t give away ideas from other mold makers. Every mold maker’s process is different and shouldn’t be transferred between mold makers without proper consideration.

4. Work with Moldmakers

Partner with your mold maker(s) early in your project. Discuss costs and consider the length of your project and part quantities. Effective collaboration leads to good results and allows both parties to prosper through a transparent and collaborative process.

5. Communication is Ongoing

Communicate regularly with your mold maker and ask for regular updates. Many mold makers provide progress reports on online platforms like Gantt charts. Stay informed about the mold and the timeline; that’s why you should be proactive and ask for updates to be scheduled for you.

6. Paying Agreements

Pay on time as mold makers incur huge upfront costs. There are different payment plans, for example down payment or milestone payments. They also have final payment upon approval of part and shipment of mold. Mold makers can customize plans to suit both parties and fairness.

7. Design Changes

Know that part design changes will affect mold specifications. Too many design changes in mold will delay lead times and increase cost. Know that part design changes frequently will require changes in mold design and will take more time and effort.

8. Completion Criteria

Define exactly when a mold is considered complete which affects the final cost. A mold is considered complete when it produces parts that meet print specifications. Small adjustments can be made to get the measurements in spec. All changes after approval will be accommodated through engineering change orders and costed accordingly.

9. Beware of Unrealistic Deals

If an offer seems too good to be true, be cautious. Although a low price may be tempting it may not deliver the value you expect. Make sure you’re focusing on quality as the effectiveness of the mold directly affects the quality of the parts.

In summary, follow these and you’ll have a smoother mold buying experience. Transparency, partnering and quality will get you the molds you need.